Product Development

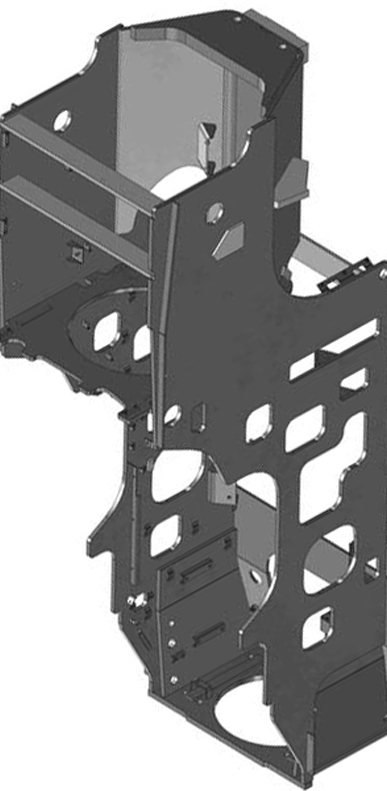

Designs begin with concepts and ideas engineered into 3D drawings using virtual software technology. From 3D developed drawings, we can easily convert with CNC programming software for automated program creation, data transfer, and machine set-up. This provides nesting capability for maximum material utilisation and optimised manufacturing technique.

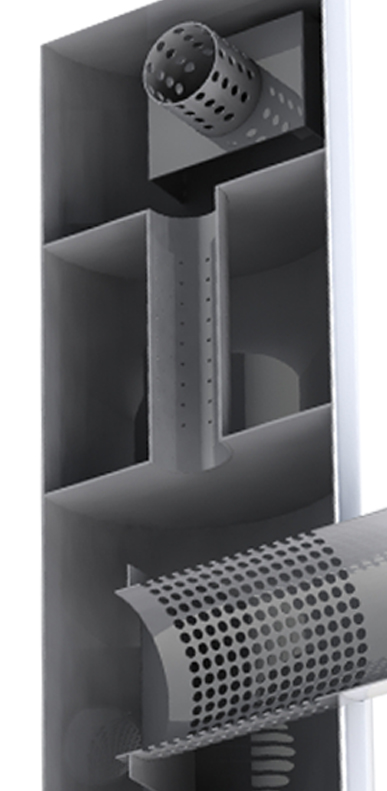

Finite Element Analysis (FEA)

Our engineers are skilled practitioners in the latest FEA software. We utilise FEA to enhance the solutions of complex projects.

The experience and ability of our engineers ensures accurate simulation of physical models. Our FEA parameter definition techniques allow us to precisely identify complex boundary constraints, interactions, and loads cases.

All FEA results are reviewed critically by senior engineers. In some cases, further validation is required in the form of physical testing.

We perform FEA studies in linear and non-linear structural analysis of stress and strain, modal analysis and natural frequencies, buckling and fatigue analysis.

Using FEA sensitivity studies and design optimisation methods, we can minimise weight and improve the function of a product, while simultaneously reducing manufacturing costs and waste.

Please contact our team for more information on how FEA could benefit your current and future projects.